3020 Standard Heater Hose

Hose construction:

Seamless EPDM inner tube and outer cover with two layers Aramid braided reinforcement layers.

Temperature range:

-40 °C -110 ºC (-40 ºF to 230 ºF)

Specification:

Meets SAE 20R3 Normal service

Uses:

Water cooling system applications

|

Part no.

|

Hose size

|

Hose I.D.

(mm)

|

Hose O.D.

(mm)

|

Working pressure

(bar)

|

Burst pressure

(bar)

|

Weight

(kg/m)

|

|---|---|---|---|---|---|---|

| 3020-06 | 06 | 10 | 17 | 10 | 30 | 0.24 |

|

3020-08

|

08

|

13 | 21 | 10 | 30 | 0.33 |

|

3020-10

|

10

|

16 | 24 | 10 | 30 | 0.40 |

|

3020-12

|

12

|

19 | 27.5 | 10 | 30 | 0.50 |

| 3020-14 | 14 | 22 | 31 | 10 | 30 | 0.60 |

| 3020-16 | 16 | 25 | 34 | 10 | 30 | 0.67 |

3021 SAE 20R3 D2 Heater Hose

Hose construction:

Seamless EPDM inner tube and outer cover with two layers braided reinforcement layers.

Temperature range:

-40 °C -125 ºC (-40 ºF to 257 ºF)

Specification:

Meets SAE 20R3 D2 specification

Uses:

Water cooling system applications

|

Part no.

|

Hose size

|

Hose size Inch

|

Hose I.D.

(mm)

|

|

Burst pressure

(bar)

|

Weight

(kg/m)

|

|

|---|---|---|---|---|---|---|---|

| 3021-06 | 06 | 3/8" | 8.90-10.10 | 16.90-18.10 | 17.2 | 0.22 | |

|

3021-08

|

08

|

½" | 11.90-13.50 | 19.90-21.50 | 17.2 | 0.26 | |

|

3021-10

|

10

|

5/8" | 15.10-16.70 | 23.10-24.70 | 17.2 | 0.33 | |

|

3021-12

|

12

|

¾" | 18.30-19.90 | 26.30-27.90 | 13.8 | 0.36 | |

| 3021-16 | 16 | 1" | 24.60-26.20 | 32.8-35.20 | 12.1 | 0.57 |

3022 Black-Hi Miler® Heater Hose

Hose construction:

Seamless EPDM inner tube and outer cover with two layers Aramid braided reinforcement layers.

Temperature range:

-40 °C -110 ºC (-40 ºF to 230 ºF)

Specification:

Meets SAE 20R3 Normal service

Uses:

Water cooling system applications

|

Part no.

|

Hose size

|

Hose size Inch |

Hose I.D.

(mm)

|

Hose O.D.

(mm)

|

Burst pressure

(bar)

|

Weight

(kg/m)

|

|---|---|---|---|---|---|---|

| 3022-05 | 05 | 5/16" | 7.30-8.50 | 14.30-15.50 | 17.2 | 0.16 |

| 3022-06 | 06 | 3/8" | 8.90-10.10 | 16.90-18.10 | 17.2 | 0.22 |

|

3022-08

|

08

|

½" | 11.90-13.50 | 19.90-21.50 | 17.2 | 0.25 |

|

3022-10

|

10

|

5/8" | 15.10-16.70 | 23.10-24.70 | 17.2 | 0.31 |

|

3022-12

|

12

|

¾" | 18.30-19.90 | 26.30-27.90 | 13.8 | 0.36 |

| 3022-16 | 16 | 1" | 24.60-26.20 | 32.8-35.20 | 12.1 | 0.54 |

Preformed

Preformed hoses are made according to customer specific design and specifications as hose marking en part number. Hose can be supplied within the SAEJ20R3 specifications or can meet the DIN73411-2B specification for original equipment manufacturing.

3035 Transmission Oil Cooling Hose

Hose construction:

Seamless CPE with a polyester braid reinforcement. Covered with a CPE outer cover. Hose has weather, oil and abrasion resistant rubber cover.

Other materials:

On request CSM and AEM tube materials and aramide braiding.

Temperature range:

-40 °C -150 ºC (-40 ºF to 300 ºF)

Specification:

Meets J1532 Type AT, Daimler MS ES-234, GM GM6260M and Ford WSS-M96D26

Compatible with:

Most modern transmission oils. Please ask for specification.

|

Part no.

|

Hose size

|

Hose I.D.

(mm)

|

Hose O.D.

(mm)

|

Working pressure

(bar)

|

Burst pressure

(bar)

|

Weight

(Kg/m)

|

|---|---|---|---|---|---|---|

|

3035-06

|

5/16"

|

7.94

|

14.3

|

4

|

70

|

0.15

|

|

3035-07

|

11/32"

|

8.73

|

15.1

|

4

|

70

|

0.17

|

|

3035-08

|

3/8"

|

9.52

|

15.9

|

4

|

62

|

0.17

|

|

3035-10

|

1/2"

|

12.7

|

19.8

|

4

|

70

|

0.24

|

3037 Engine Oil Cooling Hose (EOC)

Hose construction:

Seamless AEM with an aramid braid reinforcement. Covered with an AEM outer cover. Hose has weather, oil and abrasion resistant rubber cover.

Temperature range:

-40 °C -150 ºC (-40 ºF to 300 ºF). Peak up to 170 ºC

Specification:

Meets DBL 6257.72, GS 930010, VW TL820 48 Type B

Compatible with:

Most modern engine oils. Please ask for specification.

|

Part no.

|

Hose size

|

Hose I.D.

(mm)

|

Hose O.D.

(mm)

|

Working pressure

(bar)

|

Burst pressure

(bar)

|

Bend radius

(mm)

|

|---|---|---|---|---|---|---|

|

3037-9.5x15.5

|

9.5x15.5

|

9.5(±0.3)

|

15.5(±0.3)

|

60

|

120

|

50

|

|

3037-12.2x19.2

|

12.2x19.2

|

12.2(±0.3)

|

19.2(±0.3)

|

50

|

100

|

60

|

|

3037-15.3x23.3

|

15.3x23.3

|

15.3(±0.3)

|

23.3(±0.3)

|

50

|

100

|

75

|

3038 Turbo Charger Lubrication Hose (TCL)

Hose construction:

Seamless AEM with an aramid (hybrid) braid reinforcement. Covered with an AEM (DOGT free) outer cover. Hose has weather, oil and abrasion resistant rubber cover.

Other materials:

On request CSM and AEM tube materials and aramide braiding

Temperature range:

-40 °C -170 ºC continuous (-40 ºF to 340 ºF) up to 200 ºC peak (96h)

Specification:

Meets DBL, GS and other standard oil hose material standards

Compatible with:

Most modern transmission oils. Please ask for specification.

|

Part no.

|

Hose size

|

Hose I.D.

(mm)

|

Hose O.D.

(mm)

|

Working pressure

(bar)

|

Burst pressure

(bar)

|

Bend radius

(mm)

|

|---|---|---|---|---|---|---|

|

3038-16x24

|

16x24

|

16(±0.3)

|

24(±0.3)

|

5

|

60

|

80

|

Other dimensions on request

3142 Airbrake Hose

Hose construction:

Seamless synthetic EPDM rubber inner tube and outer cover reinforced with a two spiral polyester braiding.

Temperature range:

-40 °C -93 ºC (-40 ºF to 200 ºF)

Specification:

Meets DOT FMVSS-106

Uses:

Air brake systems

|

Part no.

|

Hose size

|

Hose I.D.

(mm)

|

Hose O.D.

(mm)

|

Working pressure

(bar)

|

Burst pressure

(bar)

|

Bend radius

(mm)

|

|---|---|---|---|---|---|---|

|

3142-04

|

0.25"

|

6.4

|

15.9

|

10

|

> 60

|

65

|

|

3142-06

|

0.37"

|

9.5

|

19.05

|

10

|

> 60

|

90

|

|

3142-08

|

0.50"

|

12.7

|

22.2

|

10

|

> 60

|

100

|

|

3142-10

|

0.521"

|

15.9

|

27

|

10

|

> 50

|

115

|

52 series Crimp Fittings 3055 Standard Barrier Hose

The crimp fittings can be used in combination of the 3055 standard airconditioning hose. For original equipment manufacturing or aftermarket repairs. Fittings are made out of steel. A full program of fitting connections in straight, 45 and 90 degrees for the different hose sizes are available. Customer specific designs can be produced according 3D model or drawing.

For more details see our catalogues or contact our Sales department.

53 series Crimp Fittings 3090 Reduced Barrier Hose

The crimp fittings can be used in combination of the 3090 reduced barrier airconditioning hose. For original equipment manufacturing or aftermarket repairs. Fittings are made out of steel. A full program of fitting connections in straight, 45 and 90 degrees for the different hose sizes are available. Customer specific designs can be produced according 3D model or drawing.

For more details see our catalogues or contact our Sales department.

54 series Burgaclip Fittings

The Burgaclip ® fittings can be used in combination of the 3090 reduced barrier airconditioning hose. For original equipment manufacturing, transport cooling or aftermarket repairs. Fittings are made out of steel. A full program of fitting connections in straight, 45 and 90 degrees for the different hose sizes are available. Customer specific designs can be produced according 3D model or drawing.

For more details see our catalogues or contact our Sales department.

Now also for sale at www.burgaclip.com

62 series Crimp Fittings 3456 Bus & Coach Hose

The crimp fittings can be used in combination of the 3456 Bus & Coach Airconditioning Hose. For original equipment manufacturing or aftermarket repairs. Fittings are made out of steel. A full program of fitting connections in straight, 45 and 90 degrees for the different hose sizes are available. Customer specific designs can be produced according 3D model or drawing.

For more details see our catalogues or contact our Sales department.

TUBING

Our tubing is made according to customer design and specifications. With brackets, stud pipes or other necessary related parts. Tubing can be made out of steel, aluminium, stainless steel or copper for original equipment manufacturing.

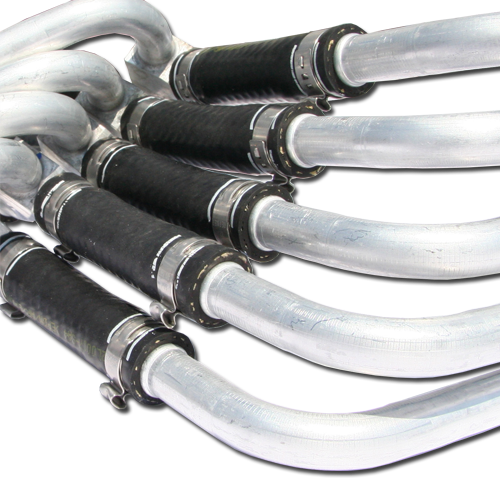

ASSEMBLIES

Hose assemblies are made according to customer design and specifications. With straight or preformed hoses. Fittings can be made out of steel, aluminium, stainless steel, copper or plastics.

Airconditioning hose assemblies are made according to customer specific design and customers specifications. Straight and preformed hoses with fittings in steel, aluminium or stainless steel to customer specific requirements and for original equipment manufacturing. Both sides can be crimped fittings, Burgaclip or a combination of both. Besides the standard fitting program every design can be taken into account.

The Federal law requires registration with the Department of Transportation for anyone producing air brake hose assemblies with swaged or crimped fittings. Fittings made out of steel or stainless steel to resist salts and chemicals for original equipment manufacturing.

Internal Heat Exchanger (IHX)

In comparison to R134a systems, the new refrigerant is at a disadvantage as R1234yf absorbs slightly less energy per unit of flow in a refrigerant cycle. In order to increase the performance level to that of R134a it is advised to use an Internal Heat exchanger (IHX). An Internal Heat exchanger (IHX) is used to transfer heat between the low side pressure and the high pressure flow circuits. Its function is to improve system performance by further sub-cooling the refrigerant being supplied to the evaporator through the refrigerant control device. In fact a tube in a tube.

Battery Management

The temperature of the battery need to be managed by cooling or heating. For both circuits, refrigerant loop for the chiller or a glycol loop foor the physic battery heating / cooling, assemblies can be made according customer requirements in steel or aluminum.

Component cooling

The electrical components need to be cooled by a glycol loop. Assemblies can be made according customer requirements in steel or aluminum.

Threadless Technology

Easy connection for airconditioning and thermal management systems. The connection as Burgaflex standard and combined with customer specific design. Connection made out of steel combined with plastic. Download leaflet at www.burgaflex.nl/norms